Indian Airport Gets Citroen Car To Make Sure You Land Safely: We Explain

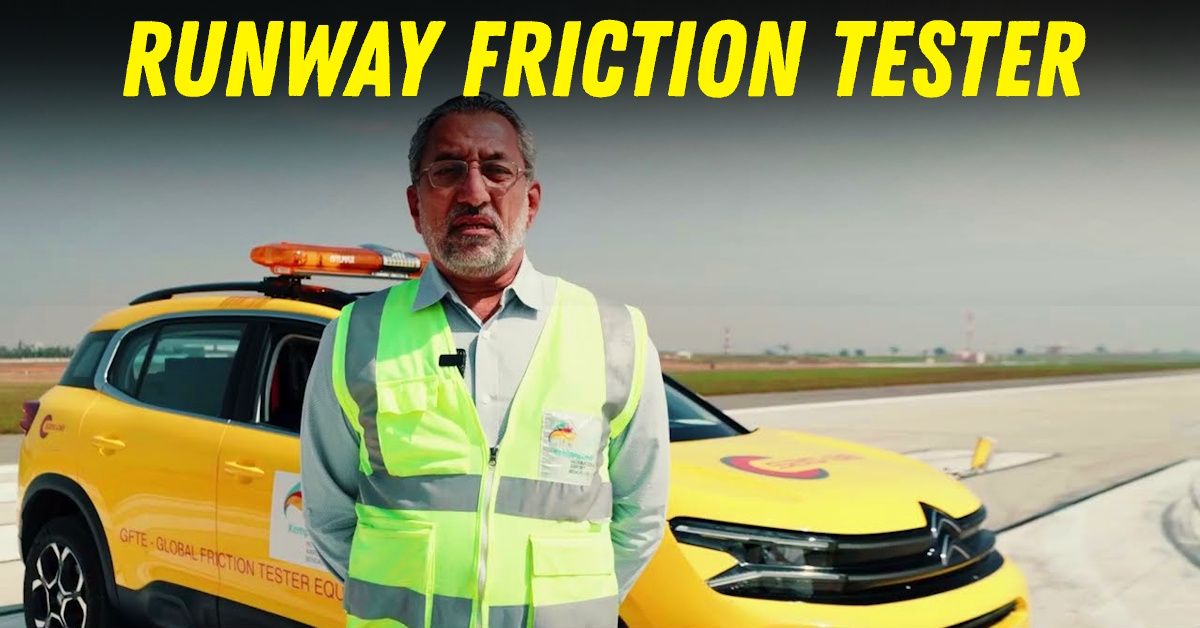

Ever wondered what the Yellow car or SUV that you might find parked on the airport tarmac is? You might have even seen them run on the runways or taxiways. Well, these vehicles are called friction testers. They play key roles in ensuring safety at airports. We will dive deeper into the process later in this article. The Bengaluru Airport (Kempegowda International Airport) has now become the first to get a 'made in India' friction testing vehicle, and it is based on a Citroen C5 Aircross SUV.

Usually, these vehicles are designed and built abroad and then shipped in. For example, the Cochin International Airport (CIAL) now has Volvo V90s as runway friction testing vehicles. These are imported units. Previously, a fleet of Saab 9-5 Station Wagons used to be employed- imports again.

It feels good to see such special operation vehicles being made in India. Regardless of the countries or regions where they are manufactured, these vehicles will have to adhere to the standards and guidelines set by the International Civil Aviation Organization (ICAO), Federal Aviation Administration (FAA) and other regulatory bodies. This vehicle is thus proof that India can manufacture top-notch aviation-related equipment maintaining global standards.

This Citroen C5 Aircross has been modified to accommodate the equipment required for runway friction testing. It has a wheel that resembles that of aeroplanes, which can be deployed when needed. This is used to measure the surface friction.

There is even a nozzle to feed running water to it while testing, to simulate landing in the rain. It is so designed to create a 1mm film of water on the runway. This nozzle feeds on a 700 L water tank that sits inside the C5 comfortably- thanks to the generous cabin room. It houses a bunch of electronic equipment and displays as well. The SUV has also been fitted with a device to measure the runway temperature.

For the safe operation of an aircraft, the runway should provide ample friction at the time of landing and take off. The friction testing equipment ensures just that. It assesses the slipperiness when the runway is wet and the data is then used to identify any 'low-grip' section. Friction tests are conducted at two speeds- 65 kph and 95 kph.

Friction values range from zero to one. The higher the value, the better the friction. The minimum recommended value for safe flight operations is 0.5 Mu (the unit of friction coefficient). Runway conditions are interpreted based on the data collected. It is classified into Good, Medium/Fair and Poor. The first will offer adequate grip and friction for safe landings. The second is acceptable but may need monitoring.

However, if the runway friction is rated poor, the airport authority would issue a NOTAM (Notice to Airmen) informing the pilots about the slippery surface and undertaking corrective actions like cleaning or rubber removal, should they be of help... There are detailed protocols for all these.

Runway Friction Testing (RFT) is an integral part of airport operations due to several reasons:

Ensuring Safety: Adequate friction is critical for safe landings and take-offs. There should be ample friction between aircraft tyres and the tarmac at the time of touch-down and the moments following it. If the runway is wet and slippery, the aircraft can take longer stopping distances or worse, can skid or loss control.

Optimising Aircraft Performance: The performance calculations for takeoff and landing are based on assumptions of a certain level of runway frinction. Accurate data on this makes sure that these calculations stand valid and the plane can operate safely within its performance limits.

Regulatory Compliance: Regulatory bodies like the ICAO and FAA have mandated periodic friction testing and cleaning on runways. Compliance with this is necessary for all airports.