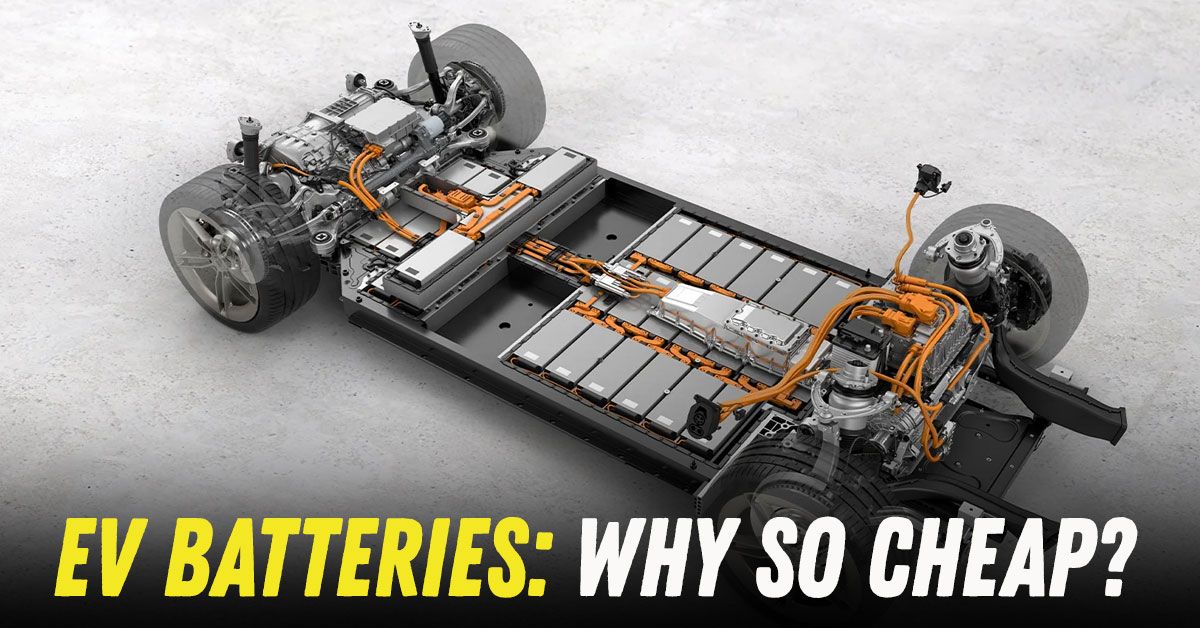

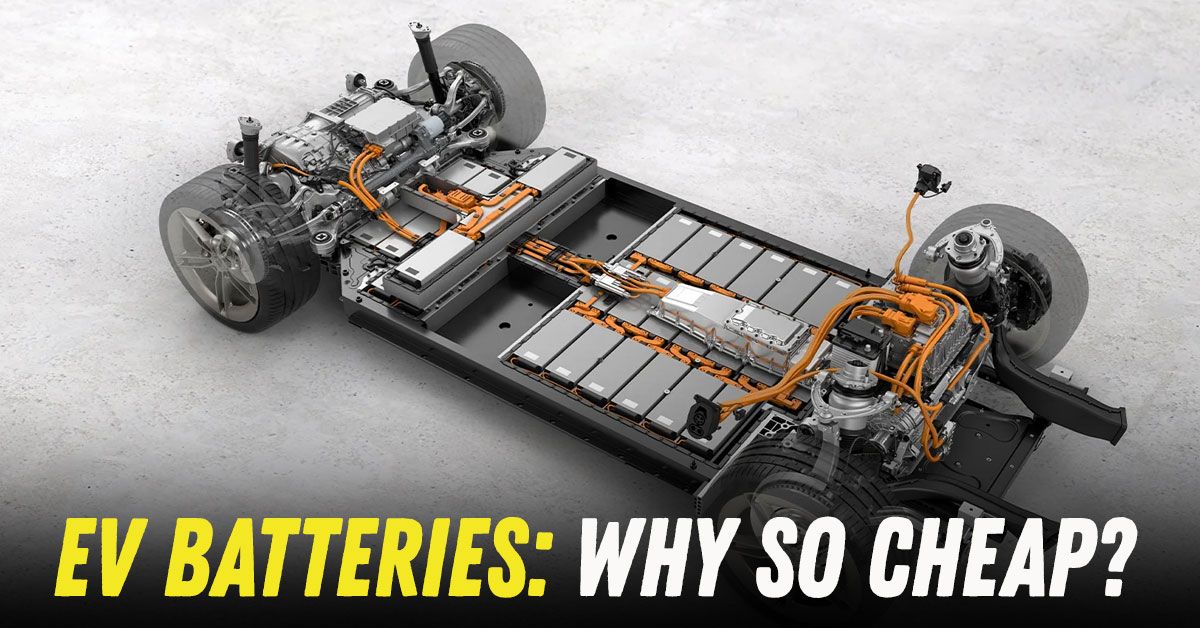

Why Are Electric Car Battery Prices Falling, And Why They'll Fall Further!

Electric Vehicles (EVs) are getting less expensive to own and a key reason for this is the falling battery prices. Previously when EVs were expensive, manufacturers used to depend completely on imported batteries and cells for them. India now has a relatively higher localisation in battery manufacturing and development than before. This, however, isn't the core reason for falling battery prices. The unfavourable demand-supply dynamics in the global EV space- according to a report by the Investment Information and Credit Rating Agency (ICRA) have caused the fall.

India is making baby steps into the local production of Lithium-ion batteries. But the global picture is different. Internationally, many major players are already storming the space with large-scale, cost-optimized production of these. In 2023, global lithium-ion battery manufacturing scaled to such heights that the produce exceeded demand by more than double the amount. This almost created a glut.

Let us try to understand this with an example. Imagine if everyone suddenly wanted to buy a certain toy. With spikes in demand, more vendors would start selling it and factories would produce them in huge volumes. This would soon create a surplus, after which the selling prices would fall.

The company would then be forced to announce massive price cuts or offers to clear the inventory. Something similar is happening with electric vehicle batteries in global markets. The glut has brought down battery prices globally resulting in a subsequent decline in import costs.

To give more context, Lithium-ion batteries used to cost $151/kWh in 2022. The next year, however, we saw them drop to $139/kWh, cheaper by 14%. In 2024, these came further down to $115/ kWh- the lowest in history!

The global oversupply could hurt India's local manufacturing efforts of Lithium batteries, by rendering them financially unviable, unless they devise ways to compete on cost, scale, or both. At the time of writing this article, 90% of EV batteries are being imported.

We believe that battery prices will continue to fall, globally. We get to see new companies foraying into the battery manufacturing space, and this could further help in bringing down the costs. With increased competition in manufacturing, the cost of the end product will be further rationalised. This will benefit buyers in the long run.

Most global players focus on manufacturing batteries with Nickel Manganese Cobalt (NMC) chemistries, which offer high energy densities. India, on the other hand, has put its focus on Lithium Ferrous Phosphate (LFP) batteries due to their cost advantages and longer longevities. Even better, LFPs are more suited for India's hot, humid climatic conditions.

Despite the bottlenecks set by the global surplus and various other factors, Indian companies are determined to produce cost-effective batteries locally. These manufacturers enjoy full policy support from the government of India. The government has plans to make electric vehicles cheaper and accessible to most, in the upcoming years.

In fact, the Union Road Transport and Highways Minister Nitin Gadkari recently made a statement that in the next six months, price parity will be achieved between petrol cars and their all-electric counterparts. Speaking at the 32nd Convergence India and 10th Smart Cities India Expo, he said "We are working on mass rapid transport on electricity."

India's push for local production of Lithium-ion batteries also has to do with freeing the country from its dependence on China for EV batteries and powertrain components, due to the worsening geopolitical ties between the two nations. To succeed in its efforts to produce them locally, India will have to not only build factories, but set up an entire ecosystem.

Nickel, Cobalt, and Lithium- the key raw materials required are sourced from within the country. However, these factories will need manufacturing equipment and machinery to be imported from countries like China and Korea. It is thus, not as easy as it sounds, to build gigafactories in India.