Hyundai’s Cold Test Revolution: No Fuel, No Emissions, Just Smarter Engines

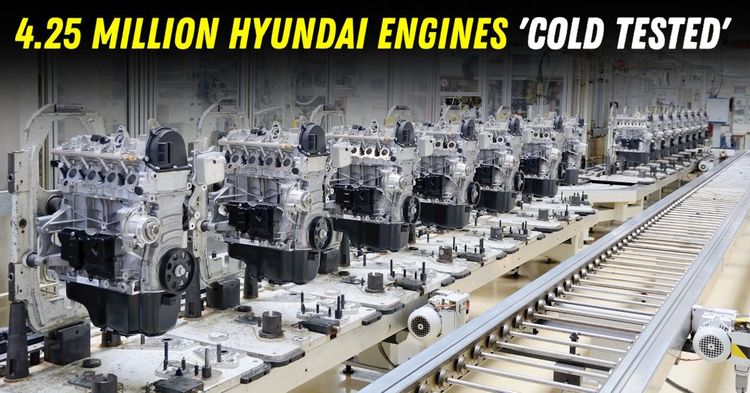

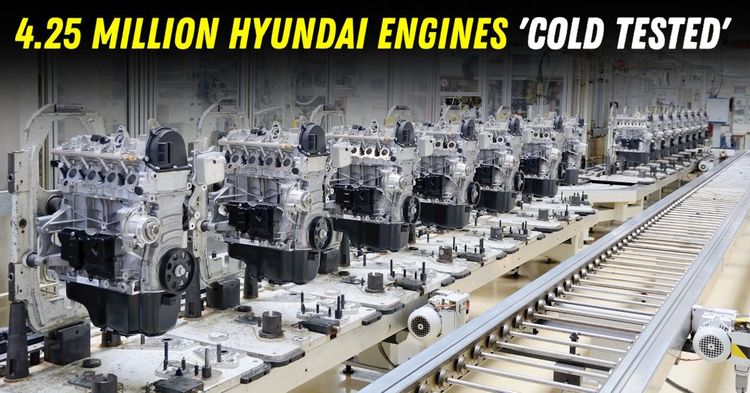

In a quiet but profound shift in automotive manufacturing, Hyundai Motor India has passed a major sustainability milestone. More than 4.25 million engines have now been tested using its fuel-free, Cold Bed Engine Testing method, marking a decisive step away from traditional, resource-intensive testing systems. This innovation, developed and adopted more than a decade ago, is not only cleaner and safer but has also saved the company nearly one million US dollars in operational costs.

As the industry debates the future of powertrains and emissions, Hyundai is refining the very way engines are built and validated. And it's doing it without burning a single drop of fuel.

At the heart of this transformation is the Cold Bed Engine Testing technology, first introduced by Hyundai Motor India back in 2013. Unlike conventional methods that require engines to run on fuel and be cooled with water or antifreeze, this system operates using electricity, primarily sourced from renewables.

Each engine is placed into a special testing bay where an electric motor spins the crankshaft. Advanced sensors then measure real-time parameters such as crankshaft angle, compression levels, and chamber pressure. In essence, the process mimics a live run without combustion, allowing engineers to verify performance without ever igniting the engine.

Beyond eliminating emissions and saving resources, the digital nature of the system means each test result is logged and analysed automatically. This not only boosts quality control but opens up vast potential for predictive maintenance and product R&D.

What makes Hyundai’s achievement noteworthy is the scale at which this innovation has been rolled out. Every single engine manufactured at its Indian facility undergoes this clean testing process. That translates to more than 4.25 million engines since inception, saving over 2 million kilograms of carbon dioxide emissions in the process.

While such environmental claims can often sound like marketing fluff, Hyundai’s numbers are backed by a clear and traceable reduction in resource consumption. No fuel used for testing means no exhaust. No coolant or water involved means zero discharge waste. And all of it is done in a fully automated, closed-loop setup.

Given that engine testing is often one of the most energy-intensive parts of vehicle production, this move is a critical step toward greening the overall supply chain.

Hyundai’s parent company has already committed to reaching net-zero emissions globally by 2045. The Indian arm’s move toward 100 percent clean engine testing fits neatly into that narrative. However, what's refreshing here is that this change doesn’t come in the form of a flashy concept car or a luxury EV, it’s rooted deep in the factory floor.

From an industry perspective, this approach is more scalable. The Cold Bed method doesn’t require any major overhaul of existing engine architecture. It simply replaces a highly wasteful testing routine with a smarter, sensor-driven one. Other manufacturers may find it harder to dismiss this as a niche innovation when the financial and environmental benefits are so tangible. Hyundai’s Cold Test Revolution: No Fuel, No Emissions, Just Smarter Engines.

This milestone comes as Hyundai celebrates its 30th year of production in India. It’s a strong message not just about its intent to decarbonise, but about the maturity of its local operations. With industry 4.0 systems, renewable-powered infrastructure, and a steady shift toward hybrid and electric mobility, the groundwork for broader sustainability goals is already being laid.